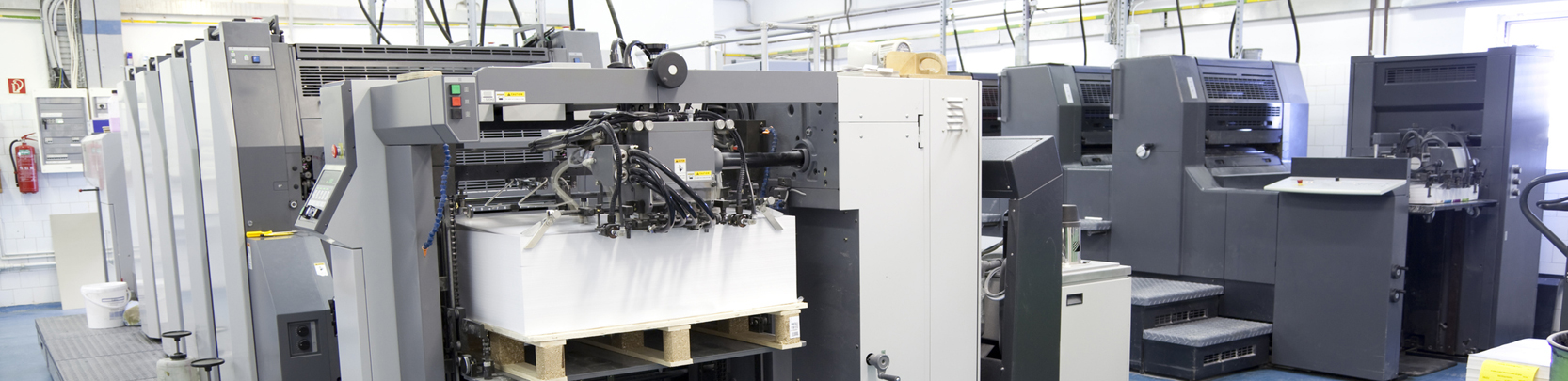

The future of printing processes and its industrial equipment has had huge changes in only a short time. With print advertising slowing and information available on the web, many newspapers will be forced to downsize. The printing process itself has become drastically different from the processes used before. Pre-press production services has become unnecessary due to the ability to go straight from computer to press without any key lining of changes using scanners and layout. The age of small print runs, more online publications and less paper usage will shape printing's future. Many of the older pre-press support equipment has become obsolete and has been selling as scrap on the used market. This has also affected the appraisal value of industrial equipment such as multi-color Heidelberg presses, bindery equipment, digital imaging equipment, and print advertising.

Many paper and pulp mills have closed due to the lessening demand for paper. In many cases paper lines been installed with the building enclosure being added after the instillation of the equipment. Because of this heavy instillation burden many paper mills are sold in-place to continue to produce product as the equipment was originally designed for.

Due to the decreased need for corrugated boxes servicing industries including automotive and furniture markets, many corrugated plants have been closed or have surplus production capacity. This has affected the values on used equipment including corrugated lines, slotters, stitchers, die cutters and printing lines.