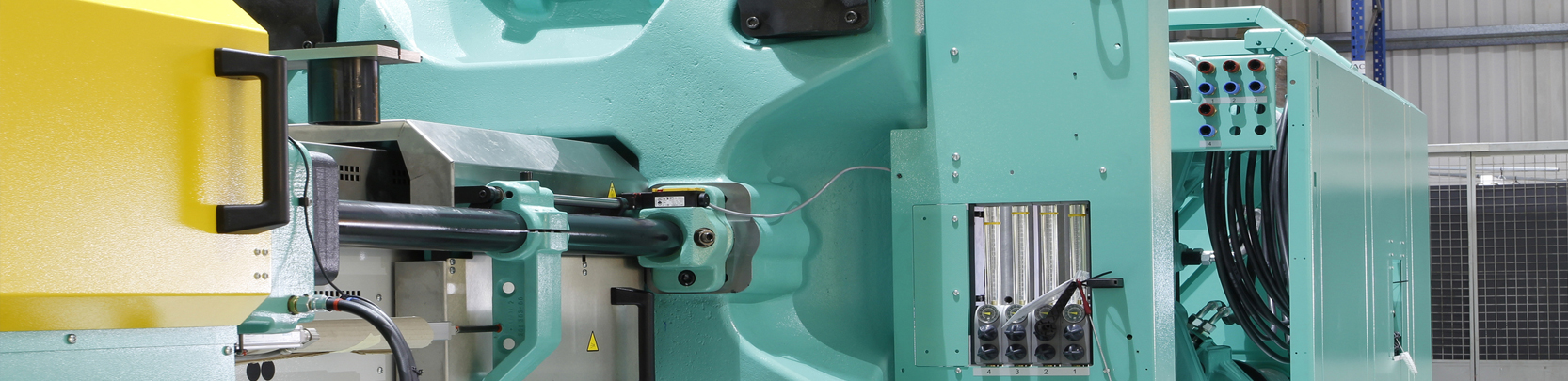

Injection molding is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. This process is used in the automotive industry for manufacturing parts, from the smallest element to entire car body panels. Material is put into into a heated barrel, mixed, and forced into a mold cavity where it cools and hardens. After a product is designed the moldmaker, or toolmaker, takes the mold from metal, usually either steel or aluminium, and precision-machined to form the features of the required part.

Injection molding had become more automated as the cost of manpower has been effected by foreign compition. Currently there is a glut of older less automated equipment available through the used equipment market. Buyers are looking for later automated machine ranging from 500 to 2,000 ton in capacity. Many of the older machines are selling to be scrapped in today's ecconomy.

The majority of Maynards' auctions are held on-site with a simultaneous webcast broadcast via the Internet. The webcast allows Maynards to reach a larger, global audience. Local buyers can benefit from the webcast as they can bid from the comfort of their offices. Another advantage of an on-line auction is that a company can quickly turn surplus assets into needed cash without disrupting employees' routines.

Maynards has been conducting equipment auctions for over 100 years. They are a trusted source and a leader in the industry.